Labeling Machines Light Series

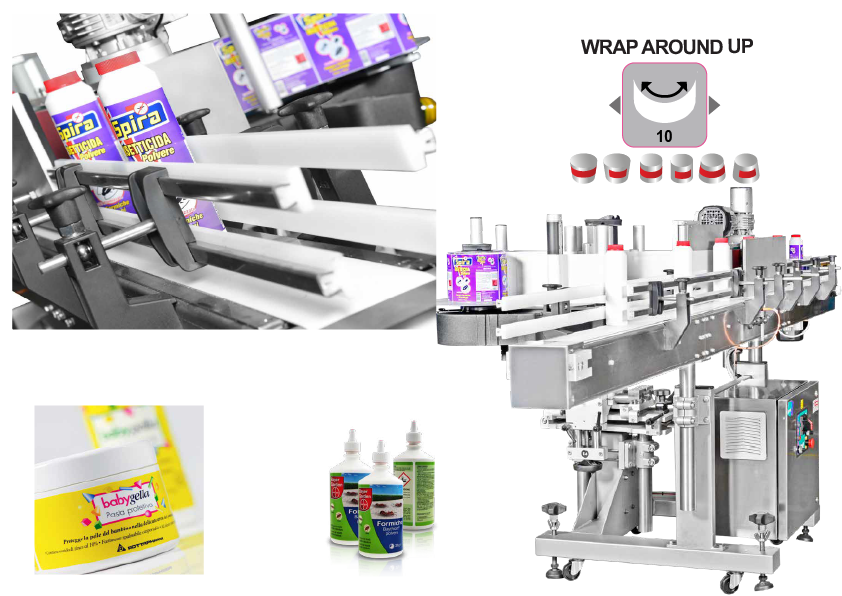

The labeling machines Light Series of Arca labeling are machines that combines high performance in a compact design. These are linear labeling systems that guarantee all the flexibility of the market in terms of labeling. No glue for feeding, heating or cleaning. Above all, very fast “setup”, without the need to replace mechanical parts (form changes) and offer high performance in all levels with an unsurpassed level of reliability.

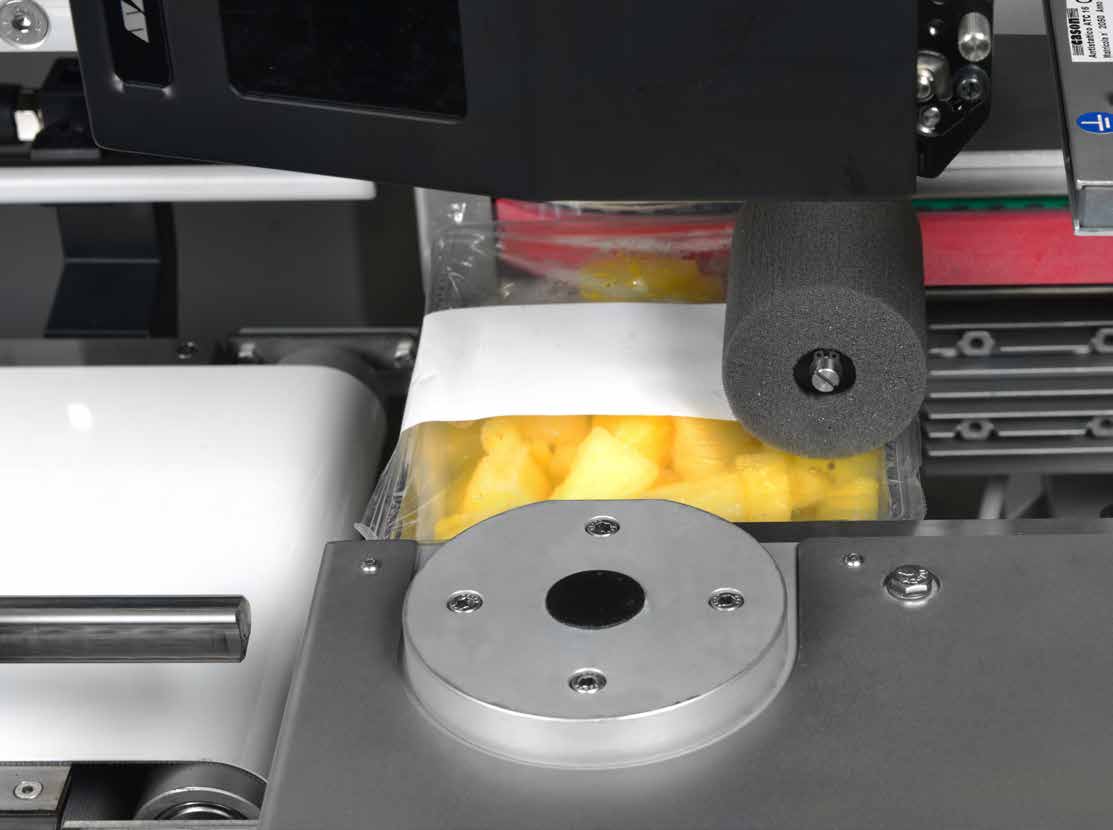

Additionally, you can combine the labeling machines Light Series of Arca labeling packaging machine with TraySealers and fillers from the Mondini House. They can be also combined with control and weighing systems.

PMS HELLAS has lifelong experience in the field of food industry equipment. As a result, it can offer packaging and processing machines as well as packaging consumables. In addition, it offers personalized solutions for all production units, small – medium – large capacity.

PMS HELLAS offers comprehensive technical support (training-spare parts-maintenance) as it knows very well what industrial production means. It has a technical department staffed by specialized technicians who offer their services all days of the week.

We will be happy to respond to your request. Together we will design the best solution according to your needs.

For more information you can visit to the site of Arca Lebeling.

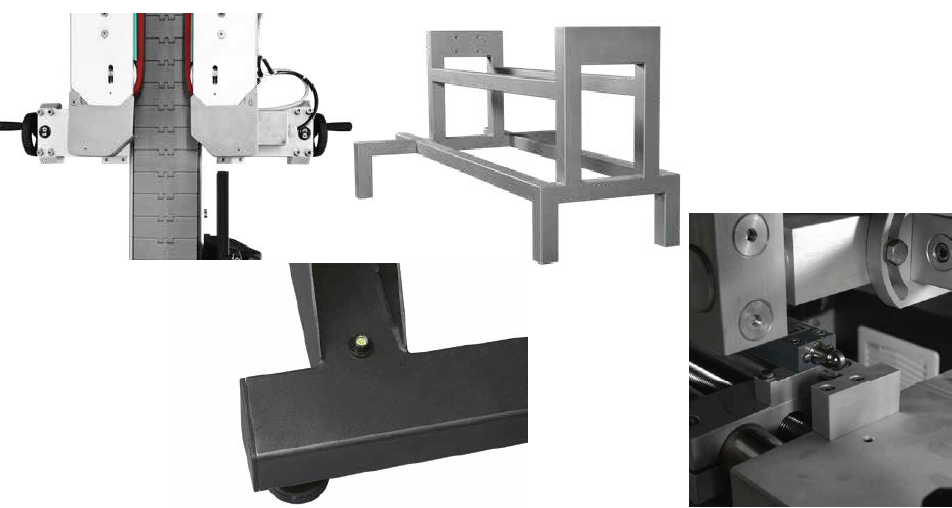

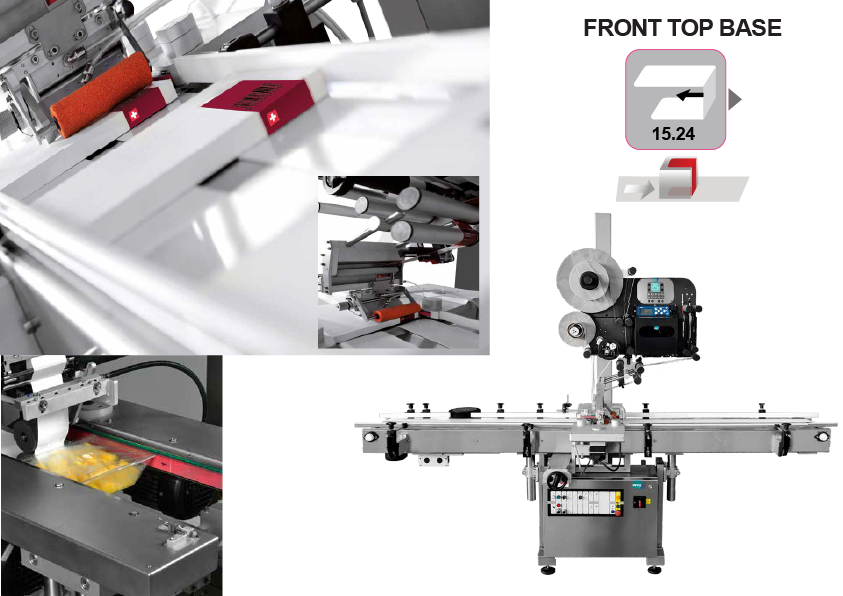

The innovative structure of Arca systems. Main bases in square sectioned steel tubing, without paneling. In order to exploit every inch of space, to be able to see, clean, wash and operate without impediment, thanks to the utmost accessibility. The main bases, stanchions, conveyors and electric installation cabinets are made entirely in steel to guarantee the utmost solidness. No vibrations, no bending. Precise and indestructible systems, intended to last a lifetime. The machines also provide ONE SIDE adjustment. That allows for working on a single handwheel and from either side of the system. Format changes are quick and guided by numerical references.

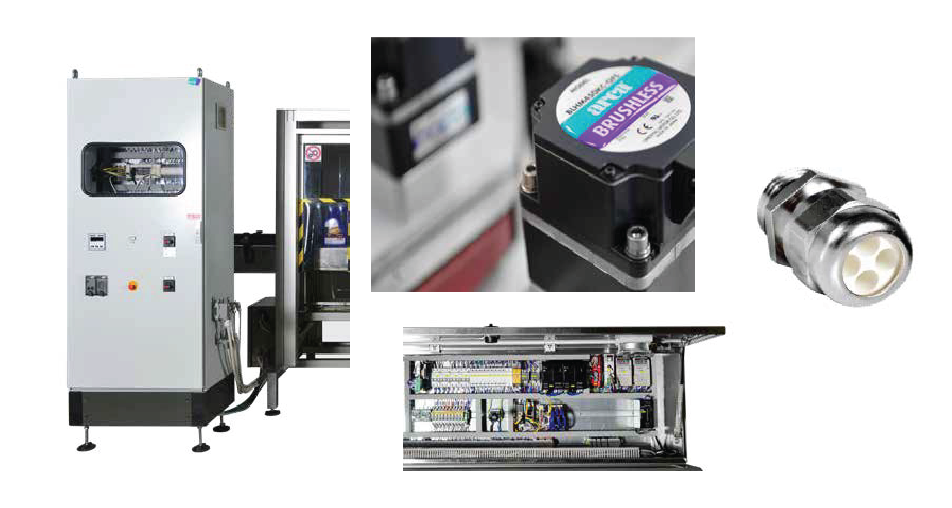

No mechanically derived movement, reducing wear and noise, improving precision. Product handling devices controlled by brushless motors; effective, practical and safe:

• constant power thrust at any speed

• suitable even at high room temperatures (50°)

• no breaches, nor oil leakage

• longer average life cycle and zero maintenance

• easy to clean

• no risk of burns (“cold” motors)

• shielded cables and metal cable blocks with IP68 grade isolation

• power circuits protected by automatic switch

• containment cabinets (with compulsory ventilation) correctly sized and easily accessible

• compliance with Electromagnetic Compatibility Guidelines (EMC 2014/30/CE) and Low Tension (LVD 2014/35/CE)

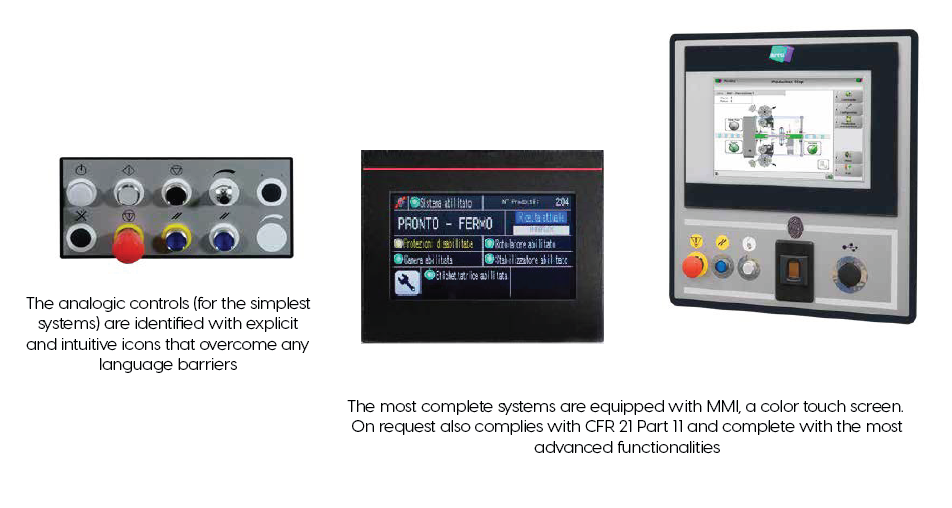

Intuitive interfaces with the most advanced features:

SYNCROSPEED: operating speeds for all product handling devices (spacers, aligners, lateral and upper stabilizers, wrapping units and adapters) are automatically synchronized to the “master” speed set for the conveyor

on-the-fly adjustments, instantaneous and accurate

alarm management is carried out according to “positive logic”. The detection of good results from all

the checks, rather than of anomalies, also ensures against breakdown of the control device

QUICK SETUP using “product programs” that memorize and recall operating settings

ability to Ethernet interface to connect to the enterprise operating system

Applications

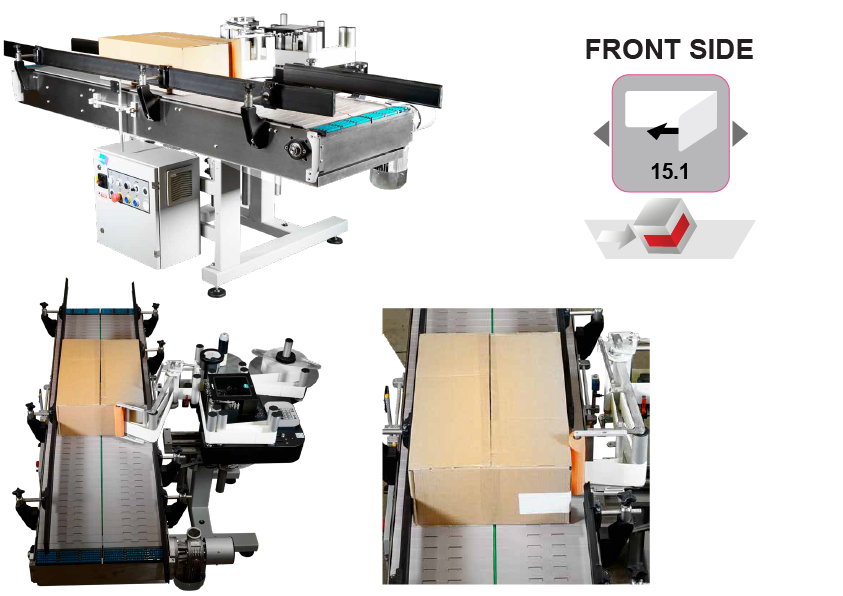

Labeler with thermal transfer printing and Concorde articulated peeler.

Iron finish (special black color on demand)

2 labelers in Non Stop configuration with “fine placement”

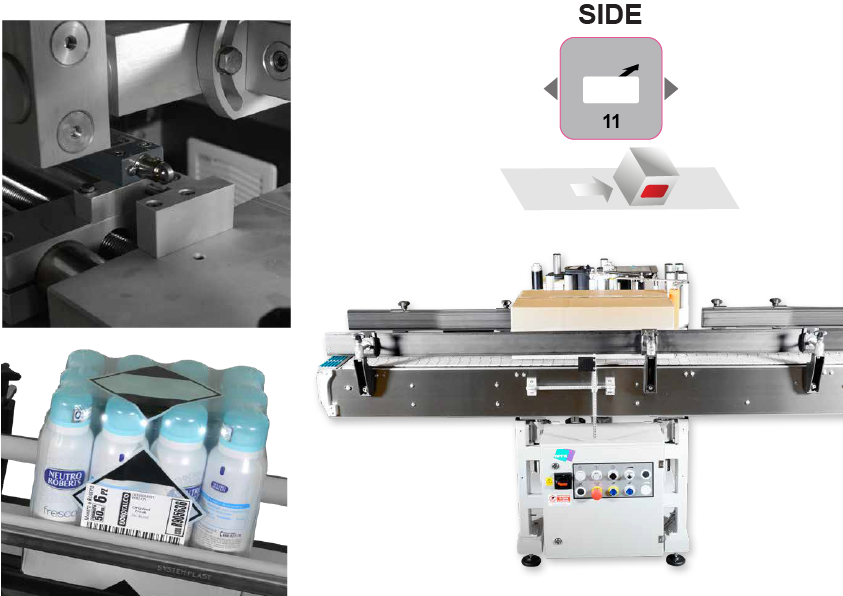

System with inkjet thermal printing unit (HP compatible). Ideal for marking in the Blow Fill Seal (BFS).

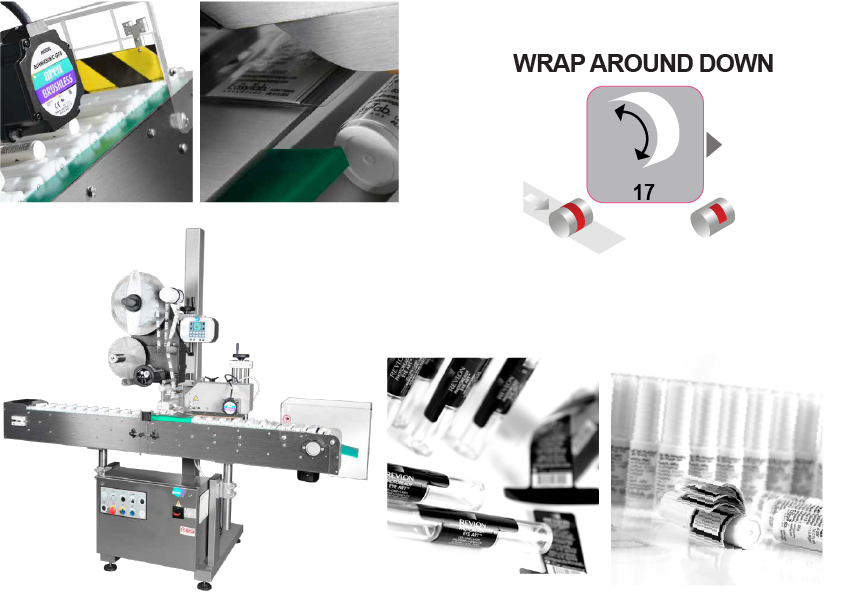

Ideal for single-dose strip labeling, thanks to the “multi-application” function of Arca labelers

Side stabilizer for limited eight products, even fragile

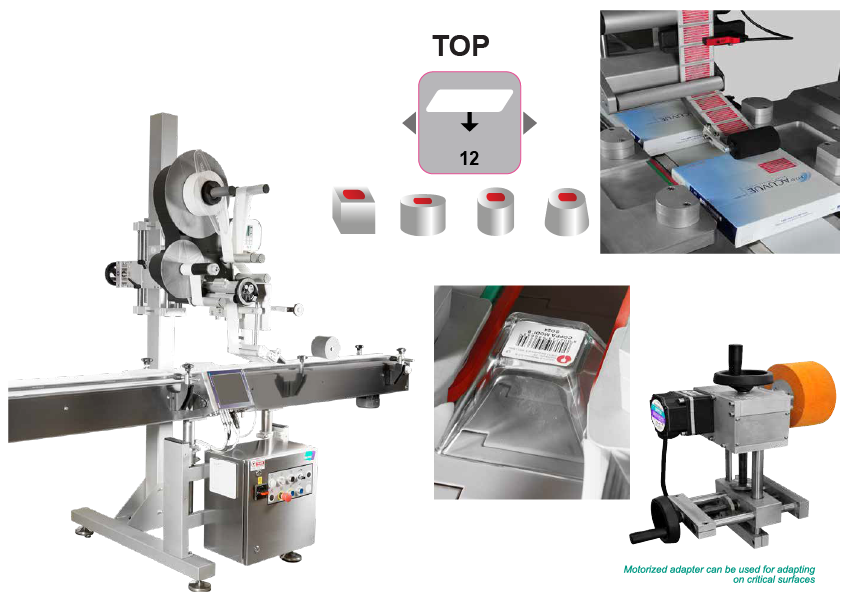

Motorized adapter can be used for adapting on critical surfaces

Top labeling on product with convex profile, via articulated peeler

Labeler with thermal transfer digital print module

Minimum clearance requirements: the lateral stabilizer picks up the products from the scale and can also download them directly onto the customer line

Cylindrical, unstable products fed in a horizontal position on an idler roller conveyor. Includes an upper wrapping unit for wraparound labeling Conveyor end with safety guard and unloading sleepway. Iron finish (special black color on demand). Labeler with thermal transfer digital print module. Indexed positioning device for “flat-lying” (horizoltal) products, with an alternate motion product feed system. When paused the product is rotated and positioned so as to detect a mark stamped on the packaging

In the Light series, the Vertical Up application is realized with the labeler positioned on the side opposite the operator side (control panel). The limit is irrelevant in “out of line” systems, being accessible from both sides anyway. Is still available a remotable control unit. It allows to operate from a unique system side