PaperSeal Former

G. Monidni once again pionners and brings the first paper tray maker – PaperSeal Former.

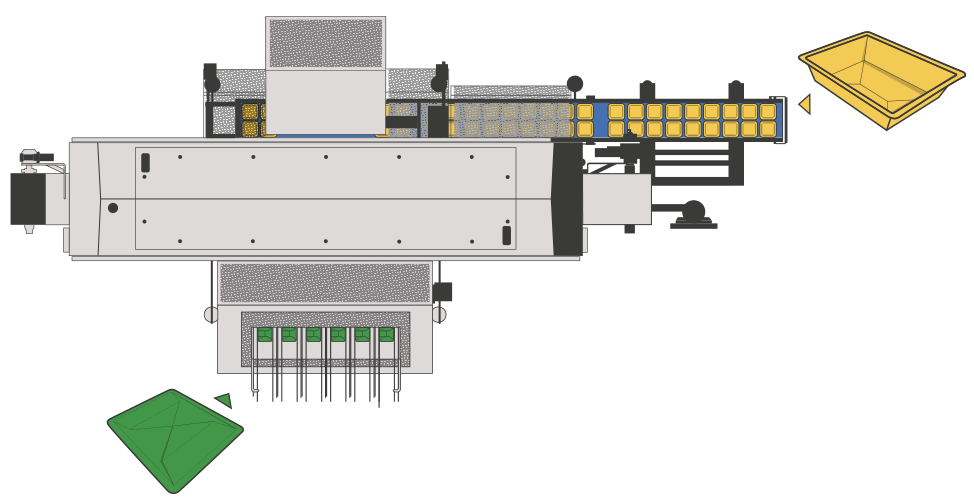

PaperSeal Former is a standalone system that can either run on its own or combine with Trave Tray Sealers to create a fully automatic line.

It is designed to optimize the production area, while allowing production with unparalleled speed. It can reach up to 13 cycles per minute.

It also has the ability to create paper containers from the entire Paper Seal series. This means that with one machine you can produce packages, both for MAP, Cook and Wedge as well as for SKIN and SLICE depending on your needs.

Pms Hellas has long experience in the field of food industry equipment. It can offer packaging and processing machines as well as packaging consumables. It also offers personalized solutions for all production units,

small – medium – large capacity.

PMS HELLAS offers comprehensive technical support (training-spare parts-maintenance) as it knows very well what industrial production means. It has a technical department staffed by specialized technicians who offer their services all days of the week.

We will be happy to respond to your request and together we will design the best solution that will be tailored to your needs.

For more information you can go to the site of G. Mondini.

• Availability of different paper trays and layers that offer technical solutions that suit each product

• Can be used for Top Seal, Modified Atmosphere (MAP), Vacuum Skin, Slice, Cook and Wedge.

•Recommended for cheeses, fresh meats, processed meats, frozen foods, ready meals, snacks, salads and fruits.

Although small in size (only 6x3 meters), PaperSeal Former guarantees high productivity.

On one side, there is the loading of flat PaperSeal boards in the magazines and the film reel for the liner, while on the opposite side the trays that are formed and piled up are released.

• Trays are delivered as flat boeards and thus significantly reduce storage and distribution costs compared to premade trays.

• The design of paper trays with zero waste technology reduces the cost of final packaging

• Sealing process that guarantees perfect sealing

• Easy separation of liner from the paperboard for simple and efficient recycling

• Flexibility on communication formats with printing and/or labelling