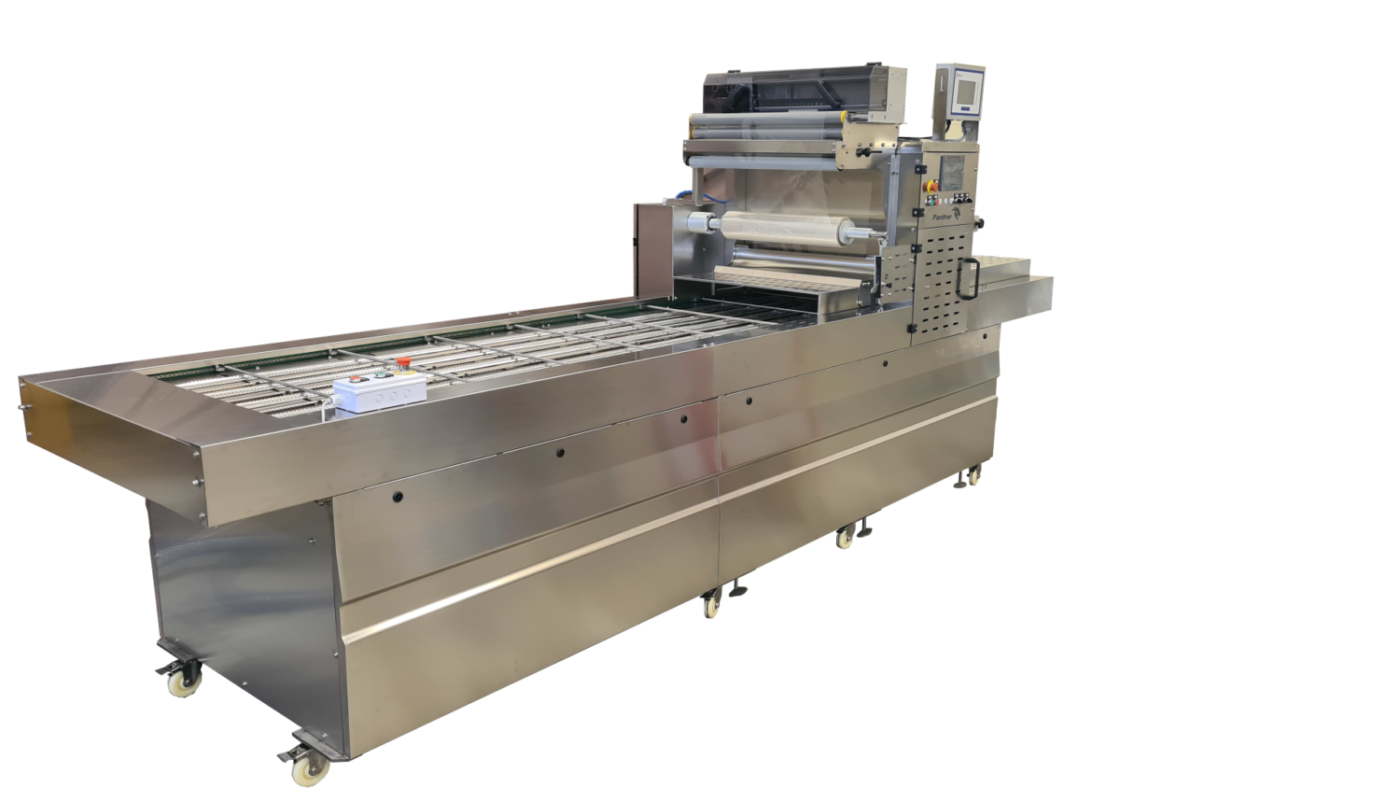

Panther

The PANTHER Tray Sealer allows significant levels of productivity for customers using pre-formed trays.

The PANTHER improves the quality of the products through a rigorous control of the gases remaining in the tray, through a precision electronic sensor, and thanks to its compliance with the European Union Regulation 1935 / 20047EC, which defines the requirements of the materials intended to enter contact with food.

You can combine the PANTHER Tray Sealer with control and weighing systems. such as Xray, Labellers and even metal detectors. It can work with new generation aluminum containers “Ready2Cook”, but also conventional plastic containers PP, PET etc.

PMS HELLAS has long experience in the field of food industry equipment. As a result it can offer packaging and processing machines as well as packaging consumables. In addition it offers personalized solutions for all production units, small – medium – large capacity.

PMS HELLAS offers comprehensive technical support (training-spare parts-maintenance) as it knows very well what industrial production means. It has a technical department staffed by specialized technicians who offer their services all days of the week.

We will be happy to respond to your request. Together we will design the best solution that will be tailored to your needs.

For more information you can visit to the site of I.DEAPACK.

Available in models

Compared to the PUMA tray sealer, the PANTHER is a larger machine, which maintains reliability, ease of cleaning and maintenance, simplified operating programs and simplicity in changing the format.

1) Denester

2) Dosing unit

3) Automatic Weigher

4) Printer

5) Photocell for printed film

6) Filter for dust or liquids

7) Special version for extra-height trays

8) Aluminum trays closing system

9) Conveyor conveying in one lane

10) Indipendent motorization of conveyor belt

11) Vacuum accelerator

| Machine dimensions | 4700x1400xh.1700 mm | Avg. cycle / min production | 10 only sealing; 7 in modified atmosphere ATM-MAP 6 in skin |

| In feed conveyor | 2 STEPS | Max tray size | 2 cavity 325x256x100mm |

| 4 cavity 163x265x100mm | |||

| Weight | 750KG | Vacuum pump | 300 m3/h STANDARD. (more upon request) |

| Frame/shell | AISI 304 | Reel core diameter | 3’’ |

| Control | PLC | Max reel diameter | 300 mm |

| Power supply | 400 V (3ph+N+PE) | ||

| Electric power | 4 Kw min | ||

| Working pressure | 6 bar | ||